Dismantling a Pumping Machine: Step-by-Step Guide

-

Understanding Progressive Pumping Machines

Progressive pumping machines are sophisticated systems designed to efficiently move fluids in industrial processes. Proper maintenance and occasional dismantling are crucial to ensure the continuous operation and performance of these machines. Let's explore a detailed guide on dismantling a pumping machine.

Step 1: Prepare for Dismantling

Before starting the dismantling process, gather the necessary tools and equipment. Ensure the pumping machine is disconnected from the power source and any associated systems to prevent accidents. Plan the dismantling process carefully to avoid damage to components.Step 2: Access and Identify Components

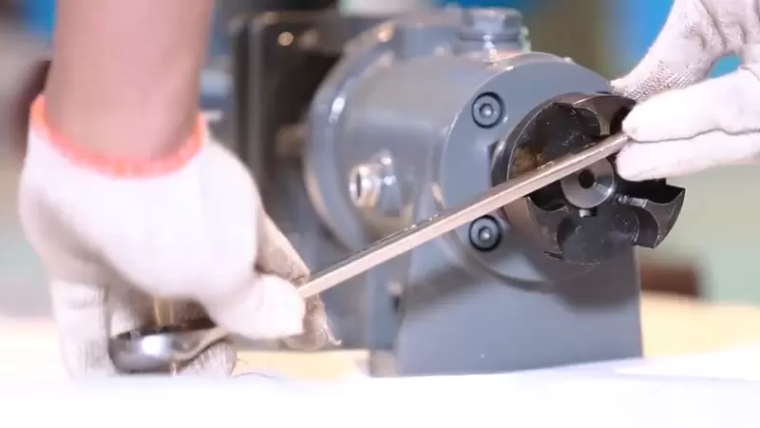

Locate the key components of the pumping machine, including the motor, stators, impellers, casings, and other internal parts. Identify these components and understand how they are interconnected within the system. Refer to the machine's manual or documentation for guidance.Step 3: Begin Dismantling Process

Start by removing the outer casing of the pumping machine to expose the internal components. Proceed by disconnecting the electrical connections and carefully removing the stators, impellers, and other stator removal tool according to the step-by-step disassembly instructions.Step 4: Replace Stators and Components

If the purpose of dismantling is to get progressive pump replacement stators, carefully uninstall these parts and install new ones. Ensure the replacement components are compatible with the pumping machine and follow proper installation procedures to maintain optimal performance.Inspect the removed components for any signs of wear, damage, or buildup that may have contributed to the machine's inefficiency. Cleaning and servicing parts can significantly improve the longevity and efficiency of the pumping machine.

By following these steps and guidelines, you can effectively dismantle a pumping machine for maintenance, repair, or component replacement purposes. Regular maintenance and timely replacements play a crucial role in ensuring the smooth operation of industrial pumping systems.